Key Benefits of VMI and JIT

-

-

- Reduced Inventory Costs: By optimizing inventory levels, VMI and JIT can significantly reduce storage costs, handling fees, and the risk of product damage or obsolescence.

- Improved Cash Flow: With less inventory on hand, businesses can free up capital that can be invested in other areas of the business.

- Increased Efficiency: VMI and JIT can streamline supply chain processes, reducing lead times and improving overall operational efficiency.

- Enhanced Sustainability: By reducing waste and minimizing transportation needs, VMI and JIT can contribute to a more sustainable supply chain. Real-World Examples

By leveraging VMI and JIT, businesses can achieve significant savings on packaging costs while improving their overall supply chain performance. By working closely with a trusted packaging supplier, companies can tailor these strategies to their specific needs and reap the benefits of a more efficient and cost-effective packaging operation.

Here are some industries that often have a significant need for custom packaging solutions:

Consumer Goods

-

-

- Electronics: Smartphones, laptops, tablets, and other electronic devices often require specialized packaging to protect them during shipping and enhance the unboxing experience.

- Electronics: Devices like smartphones, laptops, and TVs often require complex and protective packaging, driving up costs.

- Luxury Goods: High-end fashion, jewelry, and cosmetics often use premium materials and intricate designs, increasing packaging expenses.

- Toys and Games: Custom packaging can help to create a sense of excitement and anticipation for children and collectors.

- Fashion and Accessories: High-end fashion brands often use custom packaging to elevate their products and create a premium brand image.

- Cosmetics and Beauty: Custom packaging can help to differentiate beauty products and make them more appealing to consumers.

Food and Beverage

-

-

- Gourmet Food: Custom packaging can enhance the presentation of high-end food products and contribute to their perceived value.

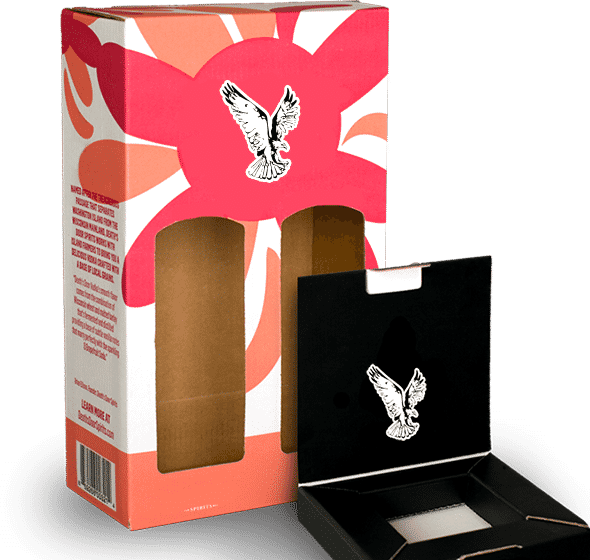

- Beverages: Wine, beer, and spirits often benefit from custom packaging to protect the product and create a visually appealing presentation.

- Confectionery: Custom packaging can add a touch of luxury to chocolates, candies, and other sweet treats.

Healthcare and Pharmaceuticals

-

-

- Medical Devices: Custom packaging is essential for protecting sensitive medical devices and ensuring their safe transportation and storage.

- Pharmaceuticals: Custom packaging can help to prevent product tampering and ensure the integrity of pharmaceutical products.

- Pharmaceuticals: Ensuring the safety and integrity of pharmaceutical products often necessitates specialized packaging with strict regulations, leading to higher costs.

Automotive

-

-

- Automotive Parts: Custom packaging is used to protect and transport a wide range of automotive parts, from engines to electronics.

- Automotive Accessories: Custom packaging can enhance the appeal of automotive accessories and create a premium customer experience.

Industrial Goods

-

-

- Machinery and Equipment: Custom packaging is often required to protect large and delicate industrial equipment during shipping and storage.

- Industrial Components: Custom packaging can help to prevent damage to small and fragile industrial components. These are just a few examples of industries that have a high demand for custom packaging.

The specific needs and requirements will vary depending on the product, its intended use, and the desired brand image.